-40%

Unitek Miyachi 2kHz High Frequency Inverter Welding Welder HF2/230 Xfmr X11 GUAR

$ 1583.99

- Description

- Size Guide

Description

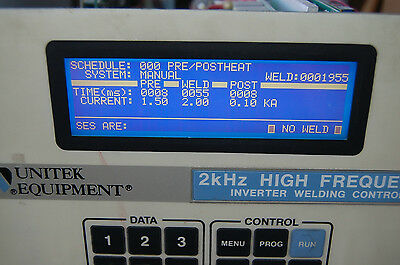

Unitek Miyachi 2kHz High Frequency Inverter Welding Control HF2/230 1-264-01Auction for Qty 1 Unitek Welding Control TESTED BY FACTORY TECH! HF2/230 , 1-264-01 , S/N 95050342

& Qty 1 HF Inverter Transformer Cat # X11/4000HF2 p/n 9-030-01-01 , s/n 95030379 ( No Cables Sold as Photographed!)

Product Description

High Frequency Inverter Welder DC Technology*

High Speed Feedback Control System for Weld Current, Voltage, or Power*

Graphical and Alpha-numeric User Interface*

Envelope function*

Input/Output Communication Ports for Automation Integration*

Optional Built-in Weld Sentry with Built-in SPCThe HF2 is a 2kHz, state-of-the-art DC inverter resistance welding control used to join small parts at high speed.

Model HF2S includes a built-in Weld Sentry for resistance weld monitoring with SPC capability.

High speed digital adaptive feedback controls weld current, voltage, or power, providing better weld consistency as compared to traditional AC or CD technologies.

Specifications

:

CONTROL SYSTEM 2KHz Pulse Width Modulated (PWM) DC welding control with constant current, voltage or power feedback operating modes.

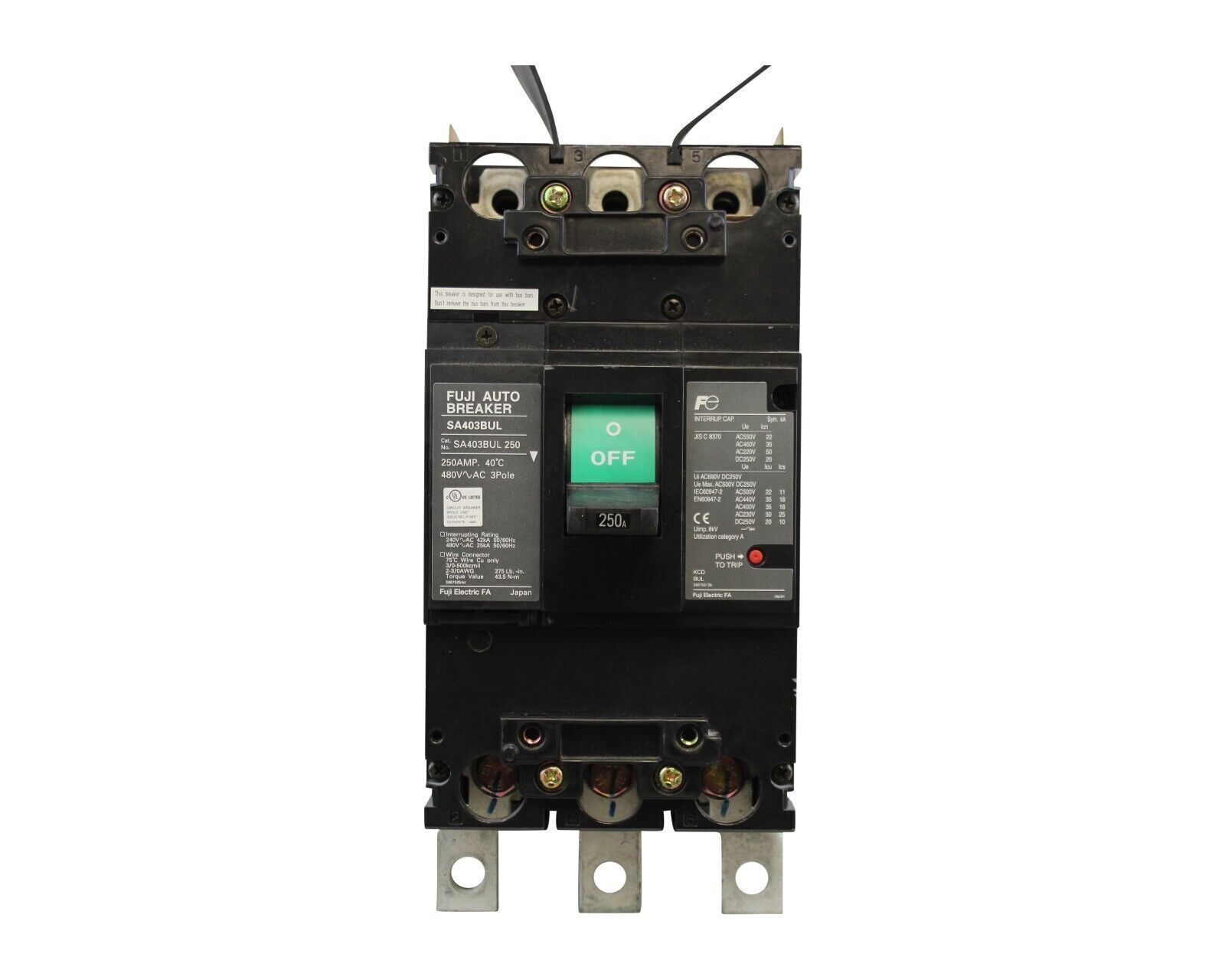

Feedback response every 250Line VoltageInput Circuit RatingThree Phase Delta, 208, 230, 380 or 460 VAC ±13%, 50/60 Hz power source.HF2/208-50A: HF2/230-50A; HF2/380-30A; HF2/460-30A.Weld Current0.05 – 4.0 kAWeld Power0.10 – 9.99 kWWeld Voltage0.1 – 5.0VWeld Period2000 milliseconds (maximum)Graphical Weld

Display:

Graphical display of programmed and actual weld current, voltage and power.Welding functions10 functions – basic, braze, dual pulse, pre/weld/post heat, pulsation, quench/temper, roll-spot, weld/repeat, up/down slope and seam, selectable by graphical or alpha-numeric user interface.

Weld Schedules:

The user can save (write) 128 different weld schedules. Weld schedules 1 through 127 can be protected. Schedule O is designed to be used as a scratchpad for schedule development.

INPUT SIGNALS:

Remote Control External Input connector provides control for the following remote control signals: emergency stop, weld inhibit and remote weld schedule selection.

Use dry relay contacts or optocouplers to control remote external input signals.Firing Switch1-level footswitch, 2-level footswitch, 2-wire firing switch, 3-wire firing switch and opto-firing switch. Use dry relay contact or opto-couplers to control input signals.

OUTPUT SIGNALS

Solid State Relays 2 user programmable solid state relays: AC-24/115 VAC @ 15VA: DC-24 VDC @ 15VA.Valve Driver OutputsTwo solid state relay outputs for controlling air actuated weld heads. Valve #1 can control a single 24/115 VAC air head.Valve #2 can control a single 24 VAC air head

. Located in Los Angeles Cal 91405